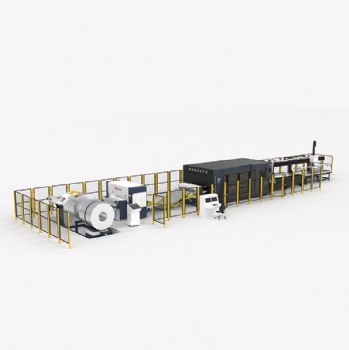

Air-cooling laser welding machine

Air-cooled type, currently supports 700-2000w power output, small size and simple operation

High portability:

Small size: The overall equipment is small and light, such as some main machines weigh only 23.5kg and the gun head weighs only 680 grams. Compared with large welding machines such as water-cooled ones, it is easier to carry and move, and can be easily placed in small vehicles or even battery vehicles, which is convenient for transportation to different work sites.

Flexible operation: There is no restriction on complex water cooling systems and related pipes, water tanks and other components. The handheld welding head is equipped with several meters of optical fiber lines, which can flexibly reach any part of the workpiece for welding. It can operate in various complex environments and small spaces. It is suitable for outdoor places without electricity. It can work by equipping outdoor lithium batteries, and has low requirements for the workplace.

Easy to operate: The control device is intuitive and simple. The machine is pre-set with common welding parameters at the factory. Users can also customize and save the required processing parameters. Ordinary workers can quickly get started after simple training. There is no need to have professional welding technical knowledge and rich experience, which reduces the technical requirements for operators and solves the problem of difficulty in hiring for enterprises.

Efficient welding: The welding speed is fast, 3-5 times that of traditional manual arc welding, and more than 4 times that of argon arc welding. It can greatly improve production efficiency and save labor costs. One machine can save at least 2 labor costs a year.

Low maintenance cost:

Air cooling technology: It adopts air cooling heat dissipation method, no need to add water, no need to add antifreeze in winter, no problems such as coolant leakage, water blockage, water pump failure, etc., which eliminates tedious maintenance work and reduces maintenance costs and risks.

Stable and durable: The structure is relatively simple, and the core light source adopts military quality. It has been tested by the market, has stable performance and long service life, and reduces production delays and maintenance costs caused by equipment failure.

Good welding quality:

Beautiful weld: It can weld common carbon steel, stainless steel, aluminum alloy, brass, copper and other metal materials. The weld is flat, smooth and beautiful, without obvious defects such as burrs and pores, reducing subsequent grinding and polishing processes, saving time and labor costs.

Small deformation: Laser welding has the characteristics of high energy density, fast heating speed and small heat-affected zone. There is less thermal disturbance to the workpiece during welding, which can effectively avoid material deformation, ensure the dimensional accuracy and shape accuracy of the welding part, and improve the overall quality and performance of the product.

Categories

Contact Us

- +86-13724554746

- +86-15291096679

- alex@dapengcnc.cn

- +86-13724554746